For A 5kw Dc Motor The Number Of Slots Per Pole Should Be

- For A 5kw Dc Motor The Number Of Slots Per Pole Should Be Lowered

- For A 5kw Dc Motor The Number Of Slots Per Pole Should Be Paid

- For A 5kw Dc Motor The Number Of Slots Per Pole Should Be Replaced

- For A 5kw Dc Motor The Number Of Slots Per Pole Should Bet

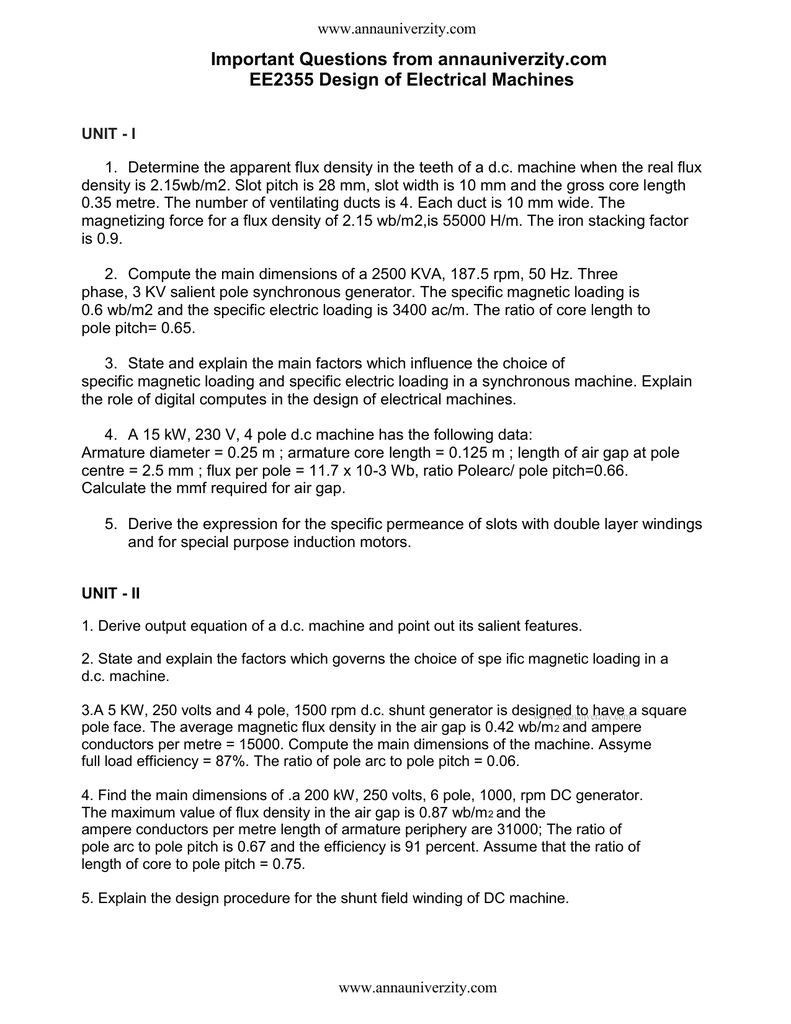

An eight pole lap-connected D C motor has 90 slots with four conductor per slot with a speed of 400 r p m calculate the total generated e m f if the useful flux is 0 8wb an electric generator delivers a load current of 24A and a terminal voltage of 250v the generator is driven by a motor whose output power is 7 5kw what is the efficiency of the. The number of slots per pole pair should be an odd integer. The number of slots per pole should be at least 9. The number of slots per pole usually lies between 9 and 16. All of the above. Pole pitch: It is defined as number of armature slots per pole. For example, if there are 36 conductors and 4 poles, then the pole pitch is 36/4=9. Coil span or coil pitch (Ys): It is the distance between the two sides of a coil measured in terms of armature slots.

This is a bit of an oddball request, but, since Steve's audience is a collection of geeks, I figured I'd try it.

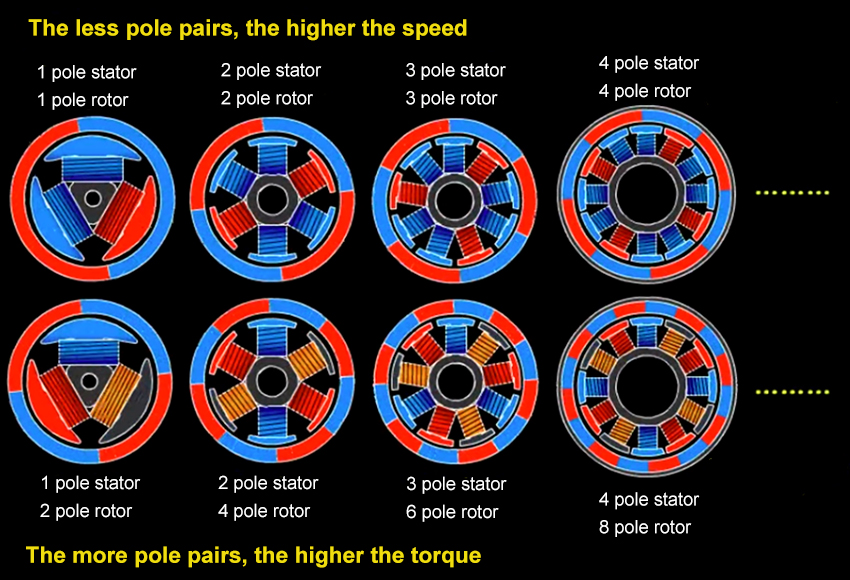

I have been a fan of alternate energy for decades. I wish to get the parts for building my own brushless DC motor (BLDC) like those used in drones, but bigger than most. I need to be able to do my own windings so I can customize things like wire size, turns, wiring pattern, etc. I will then do experiments as to the power of the motor, speed, and use as a generator, etc. I have no machine shop, so I need ready made parts (and knowledge). I'm looking at an outrunner configuration with probably 50 mm + diameter and 12, 24, or 36 teeth (or coils). The number of magnet poles can be slightly less than, equal to, or slightly more than the number of teeth. Don't know about other parameters but I'm thinking about a Kv of 100 or less. None of this is set in stone. I've found some sources for stators (the part with the coils), but have not found the parts for matching frames and rotors. Yes, I could take apart an existing motor, but big ones tend to be expensive, and hard to disassemble without damage.

For those of you that might be interested, here are some resources I've already found.

The Moderator of this thread is Ron, but it's not me.

Re-winding and building motors, tips and tricks, checks and tests - RC Groups

My upcoming week is very busy so I may not be as active here on the forum. But, all help is appreciated and I'll reply when I can.

Ron

For A 5kw Dc Motor The Number Of Slots Per Pole Should Be Lowered

For A 5kw Dc Motor The Number Of Slots Per Pole Should Be Paid

- Pole pitch: It is defined as number of armature slots per pole. For example, if there are 36 conductors and 4 poles, then the pole pitch is 36/4=9.

- Coil span or coil pitch (Ys): It is the distance between the two sides of a coil measured in terms of armature slots.

- Front pitch (Yf): It is the distance, in terms of armature conductors, between the second conductor of one coil and the first conductor of the next coil. OR it is the distance between two coil sides that are connected to the same commutator segment.

- Back pitch (Yb): The distance by which a coil advances on the back of the armature is called as back pitch of the coil. It is measured in terms of armature conductors.

- Resultant pitch (Yr): The distance, in terms of armature conductor, between the beginning of one coil and the beginning of the next coil is called as resultant pitch of the coil.

For A 5kw Dc Motor The Number Of Slots Per Pole Should Be Replaced

[Also read: Armature reaction in DC machines]

[Also read: Armature reaction in DC machines]